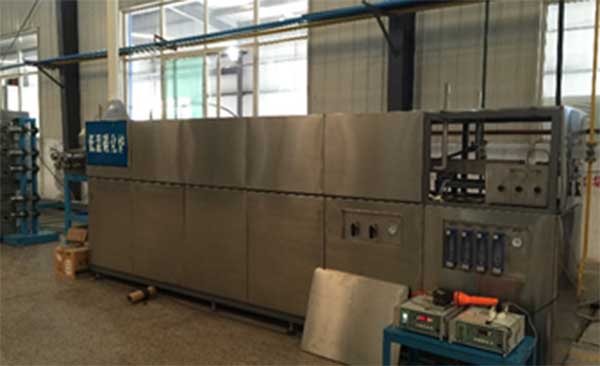

The mass-production continuous carbonization furnace is a continuous high-temperature carbonization furnace that can mass-produce high-performance carbon fiber, which is improved by our company based on many years of experience. It is specially used for continuous high-temperature carbonization of high-performance carbon fiber materials at 500-1600 degrees.

The mass-production continuous carbonization furnace is a continuous high-temperature carbonization furnace that can mass-produce high-performance carbon fiber, which is improved by our company based on many years of experience. It is specially used for continuous high-temperature carbonization of high-performance carbon fiber materials at 500-1600 degrees.

The design of the entire furnace body fully considers and understands the carbonization preparation process of high-performance carbon fiber material high-temperature carbonization, as far as possible to meet its key and special requirements, and fully consider the simple and practical principles of large-scale furnace body installation and maintenance.

In the actual use process of mass-production continuous carbonization furnace to produce high-performance carbon fiber, all parameters have reached the domestic advanced level. The temperature is uniform, the operation is simple, and the parameters are stable. After simple maintenance once a year, it can achieve long-term continuous Stable operation.

The mass-production continuous carbonization furnace is a continuous high-temperature carbonization furnace that can mass-produce high-performance carbon fiber, which is improved by our company based on many years of experience. It is specially used for continuous high-temperature carbonization of high-performance carbon fiber materials at 500-1600 degrees.

The design of the entire furnace body fully considers and understands the carbonization preparation process of high-performance carbon fiber material high-temperature carbonization, as far as possible to meet its key and special requirements, and fully consider the simple and practical principles of large-scale furnace body installation and maintenance.

• The design of the entire furnace body fully considers and understands the carbonization preparation process of high-performance carbon fiber material at high temperature to meet its key and special requirements as much as possible.

• Fully consider the simple and practical principles of large-scale furnace body during installation and maintenance. It includes a muffle furnace hearth made of high-strength graphite, with a mouth width of 1000-2000mm and a length of 12000mm, divided into 10-12 temperature zones. , Among them, 7-9 controllable temperature zones, the temperature can be controlled at 500-1600 degrees, and the remaining 3 temperature zones are natural temperature buffers from high to low temperature.

• The furnace mouth can be segmented, so that the actual carbon fiber does not shrink or expand during actual carbonization, and can well ensure the temperature gradient and temperature uniformity.

• High-power graphite heating elements uniformly distributed up and down. The power supply adopts phase-shifting voltage regulation, which has good continuity and low impact; after output to the transformer, it is rectified into DC by a fully-controlled rectifier bridge and then added to the graphite heating element.

• The insulation structure composed of graphite hard felt and low thermal conductivity insulation cotton is uniformly distributed around, and at the same time, there are inlet and outlet gas sealing devices, inlet and outlet water cooling devices, and inlet and outlet temperature buffers, high-precision temperature control curves and overall temperature. Monitoring system, precise oxygen content and dew point tracking system of protective gas at each point in the furnace, and gas micro-pressure test system at each point in the furnace.

• The parameters of the high-temperature carbonization furnace produced by our company have reached the domestic advanced level during the actual use of the production of high-performance carbon fiber. The temperature is uniform, the operation is simple, and the parameters are stable. After simple maintenance once a year, it can achieve long-term continuous Stable operation.

| Model | CX-CCF40/120 | CX-CCF50/150 | CX-CCF60/180 | CX-CCF60/200 |

|---|---|---|---|---|

| Max Working Temperature | 1600°C | |||

| Usable Space (mm) W×H(customized)×L | 400×200×1200 | 500×200×1500 | 600×200×1800 | 600×200×2000 |

| Number of Heating Zones(customized) | 3 | 3 | 3 | 3 |

|

Temperature Uniformity (ΔT between 1000°C and 2200°C) |

±10°C | |||

| Max. Heat-up Rate (CEDRT)* | 15°C/min | |||

| Heating Power | 75 KW | 90 KW | 120 KW | 160 KW |

| Working Atmosphere | Inert Gas (Ar or N2) | |||

| Supply Voltage | 3P, 380V, 50Hz/60Hz | |||

| Cooling Water Pressure | 1.5~2.5 bar | |||

| Cooling Water Temperature | ≤28°C | |||

* CEDRT: Clean, Empty, Dry, Room Temperature Furnace