Used for high-temperature graphitization of various powdered carbon and graphite materials. Cylindrical working chamber is especially suitable for high temperature treatment of powder and rolls. This furnace type is widely used in the graphitization process of polyimide thermal conductive graphite sheet (PI graphite sheet)

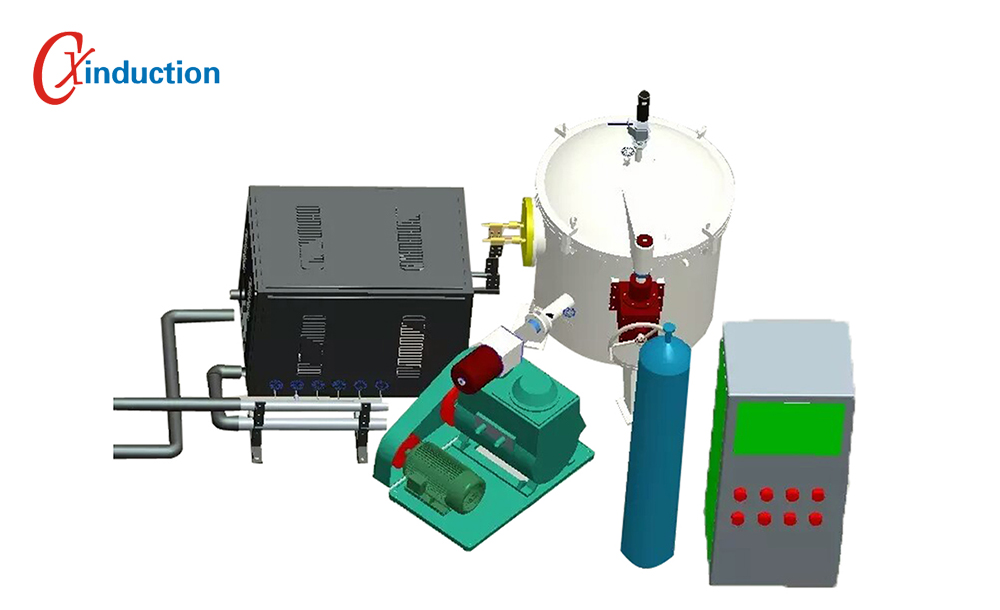

CX-GF…/…VT series are vertical top loading batch type induction heating furnaces with cylindrical hot zone shape. Vertical loading, convenient for temperature measurement and aiming. The Cylindrical working chamber has higher heating efficiency.

Maximum operating temperature of 3000°C used for high-temperature graphitization of various powdered carbon and graphite materials. A cylindrical furnace chamber is especially suitable for the high-temperature treatment of powder and rolls. This furnace type is widely used in the graphitization process of polyimide thermal conductive graphite sheets (PI graphite sheet).

These furnaces use medium frequency induction heating method. A water cooled induction coil installed inside the furnace. At the center of the coil, there is a graphite crucible as the susceptor for the induction current, surrounded by carbon felt as the insulation material.

CX-GF…/…VT series are vertical top loading batch type induction heating furnaces with cylindrical hot zone shape. Vertical loading, convenient for temperature measurement and aiming. The Cylindrical working chamber has higher heating efficiency.

Maximum operating temperature of 3000°C used for high-temperature graphitization of various powdered carbon and graphite materials. A cylindrical furnace chamber is especially suitable for the high-temperature treatment of powder and rolls. This furnace type is widely used in the graphitization process of polyimide thermal conductive graphite sheets (PI graphite sheet).

These furnaces use medium frequency induction heating method. A water cooled induction coil installed inside the furnace. At the center of the coil, there is a graphite crucible as the susceptor for the induction current, surrounded by carbon felt as the insulation material.

• Continuously working temperature is 2850℃;

• Working atmosphere in the furnace: nitrogen or other inert gases, etc.;

• Temperature measurement: far-infrared optical temperature measurement, temperature measurement range 1000~3200℃ or 600~3100℃, temperature measurement accuracy: 0.2~0.75%;

• Limit heating rate: 15°C/min for room temperature -1500°C, 10°C/min for 1500-2500°C, 5°C/min for 2500-3000°C;

• Furnace temperature uniformity: ≤±15℃, (equipment with internal working space diameter Φ500mm* height 1000mm, measured at a constant temperature of 1750℃ for 30 minutes);

• Temperature control: PID intelligent program control and manual control; temperature control accuracy: ±1℃;

• Control mode: PLC programming automatic control, instrument real-time recording;

• With a USB interface, the recorded historical data can be transferred to the computer via a U disk at any time, with password protection, and the password can be exported to ensure the confidentiality of the process;

• Heating method: intermediate frequency induction graphite crucible heating;

• Protection device: all-round water and electricity measurement and control and alarm;

• The unique induction coil adopts 5 times of insulation treatment, which completely solves the application problem of induction coil or high-temperature insulation, and ensures that the coil can maintain good insulation performance under the conditions of corundum aging and cracking, which can effectively prevent the coil from ignition and current leakage. And other phenomena.

The supporting systems of the complete set of equipment include: vacuum system, gas purification system, cooling system, exhaust gas treatment, DCS central control system

| Model | CX-GF20/30VT | CX-GF30/40VT | CX-GF40/100VT | CX-GF50/100VT | CX-GF60/100VT | CX-GF60/160VT |

|---|---|---|---|---|---|---|

| Max Working Temperature | 3000°C | |||||

| Usable Space (mm) W×H×L | Φ200×300 | Φ300×400 | Φ400×1000 | Φ500×1000 | Φ600×1000 | Φ600×1600 |

| Max. Loading Capacity(L) | 9 | 28 | 125 | 196 | 282 | 452 |

|

Temperature Uniformity (ΔT between 1000°C and 2200°C) |

±10°C | |||||

| Max. Heat-up Rate (CEDRT)* | 15°C/min (RT~1500°C), 10°C/min (1500°C~2500°C), 5°C/min (2500°C~3000°C) | |||||

| Heating Power | 100 KW | 160 KW | 200 KW | 250 KW | 300 KW | 350 KW |

| Frequency | 2500 Hz | 2000 Hz | 2000 Hz | 1500 Hz | 1500 Hz | 1500 Hz |

| Ultimate Vacuum (CEDRT)* | 1.2×10-3 mbar | |||||

| Optional High Vacuum (CEDRT)* | 5×10-5 mbar | |||||

| Pressure Rise | 6.7×10-3 mbar/hr | |||||

| Working Atmosphere |

High Vacuum (Optional) / Vacuum / Inert Gas (Ar or N2) Vacuum and high vacuum atmosphere is only permitted up to 2200°C. |

|||||

| Supply Voltage | 3P, 380V, 50Hz/60Hz | |||||

| Cooling Water Pressure | 1.5~2.5 bar | |||||

| Cooling Water Temperature | ≤28 °C | |||||

* CEDRT: Clean, Empty, Dry, Room Temperature Furnace

| Model | CX-GF40/100VT-II | CX-GF50/100VT-II | CX-GF60/100VT-II | CX-GF90/160VT-II |

|---|---|---|---|---|

| Max Working Temperature | 3000°C | 2650°C | ||

| Usable Space (mm) W×H×L | Φ400×1000 | Φ500×1000 | Φ600×1600 | Φ900×1600 |

| Max. Loading Capacity | 125 | 196 | 452 | 1017 |

|

Temperature Uniformity (ΔT between 1000°C and 2200°C) |

±10°C | |||

| Max. Heat-up Rate (CEDRT)* | 15°C/min (RT~1500°C), 10°C/min (1500°C~2500°C), 5°C/min (2500°C~3000°C) | |||

| Heating Power | 200 KW | 250 KW | 350 KW | 500 KW |

| Frequency | 2000 Hz | 1500 Hz | 1500 Hz | 1000 Hz |

| Ultimate Vacuum (CEDRT)* | 1.2×10-3 mbar | |||

| Optional High Vacuum (CEDRT)* | 5×10-5 mbar | |||

| Pressure Rise | 6.7×10-3 mbar/hr | |||

| Working Atmosphere |

High Vacuum (Optional) / Vacuum / Inert Gas (Ar or N2) Vacuum and high vacuum atmosphere is only permitted up to 2200°C. |

|||

| Supply Voltage | 3P, 380V, 50Hz/60Hz | |||

| Cooling Water Pressure | 1.5~2.5 bar | |||

| Cooling Water Temperature | ≤28 °C | |||

* CEDRT: Clean, Empty, Dry, Room Temperature Furnace

| Model | CX-GF50/100VT-IV | CX-GF60/160VT-IV | CX-GF90/160VT-IV |

|---|---|---|---|

| Max Working Temperature | 3000°C | ||

| Usable Space (mm) W×H×L | Φ500×1000 | Φ600×1000 | Φ900×1600 |

| Max. Loading Capacity | 196 | 452 | 1017 |

|

Temperature Uniformity (ΔT between 1000°C and 2200°C) |

±10°C | ||

| Max. Heat-up Rate (CEDRT)* | 15°C/min (RT~1500°C), 10°C/min (1500°C~2500°C), 5°C/min (2500°C~3000°C) | ||

| Heating Power | 250 KW | 350 KW | 500 KW |

| Frequency | 1500 Hz | 1500 Hz | 1000 Hz |

| Ultimate Vacuum (CEDRT)* | 1.2×10-3 mbar | ||

| Optional High Vacuum (CEDRT)* | 5×10-5 mbar | ||

| Pressure Rise | 6.7×10-3 mbar/hr | ||

| Working Atmosphere |

High Vacuum (Optional) / Vacuum / Inert Gas (Ar or N2) Vacuum and high vacuum atmosphere is only permitted up to 2200°C. |

||

| Supply Voltage | 3P, 380V, 50Hz/60Hz | ||

| Cooling Water Pressure | 1.5~2.5 bar | ||

| Cooling Water Temperature | ≤28 °C | ||

* CEDRT: Clean, Empty, Dry, Room Temperature Furnace