Artificial graphite material, as one of the main materials of lithium-ion batteries, plays a key role in the performance design of lithium-ion batteries. The physical and chemical indicators of artificial graphite materials, such as particle size distribution, tap density, specific surface area, capacity and other key indicators, have an important impact on the performance design and performance of lithium-ion batteries.

Graphitization is the main process in the production process of artificial graphite. High temperature graphitization furnace is mainly used as the main equipment. Through induction heating, coke powder is transformed into artificial graphite material at high temperature (≥2 800 ℃). The graphitization process mainly includes a power-up heating stage and a cooling-out stage. Among them, the cooling and tapping stage is accompanied by the oxidation of the carbon material at a high temperature, which will cause changes in the particle morphology and structure of the artificial graphite material. This will affect various physical and chemical indicators of artificial graphite materials, and eventually lead to changes in the performance of lithium-ion batteries.

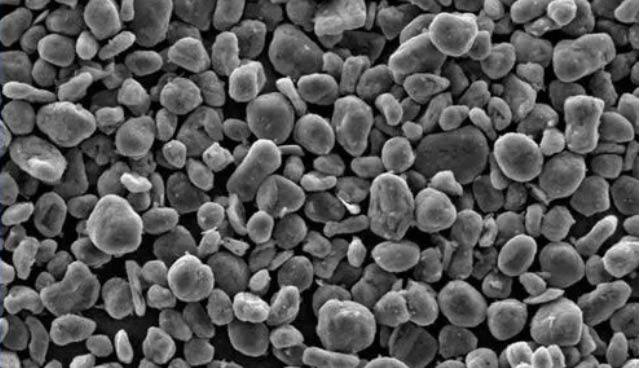

(1) High temperature oxidation will affect the key indicators of artificial graphite: specific surface area, tap density, specific capacity, initial efficiency and powder compaction density indicators. With the strengthening of oxidation, the specific surface area and powder compaction density increased, showing a positive correlation trend; the tap density, specific capacity, first efficiency decreased, showing a negative correlation trend.

(2) The oxidative etching starts from the edge surface of the artificial graphite and gradually penetrates into the interlayer structure of the graphite, causing the destruction of the dense structure of the artificial graphite, and finally leading to the exfoliation of the artificial graphite structure. adverse effects such as decreased life expectancy.