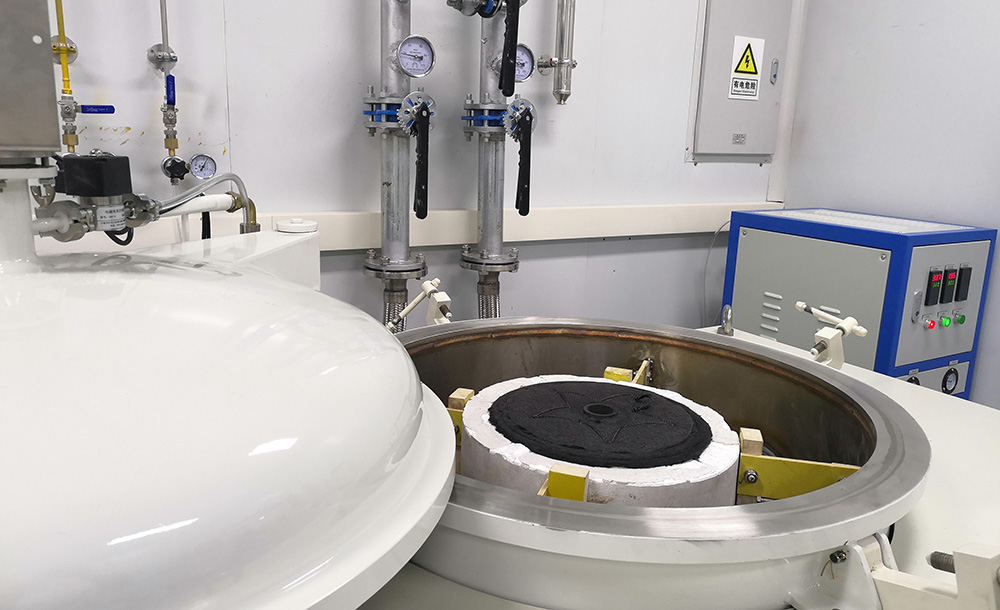

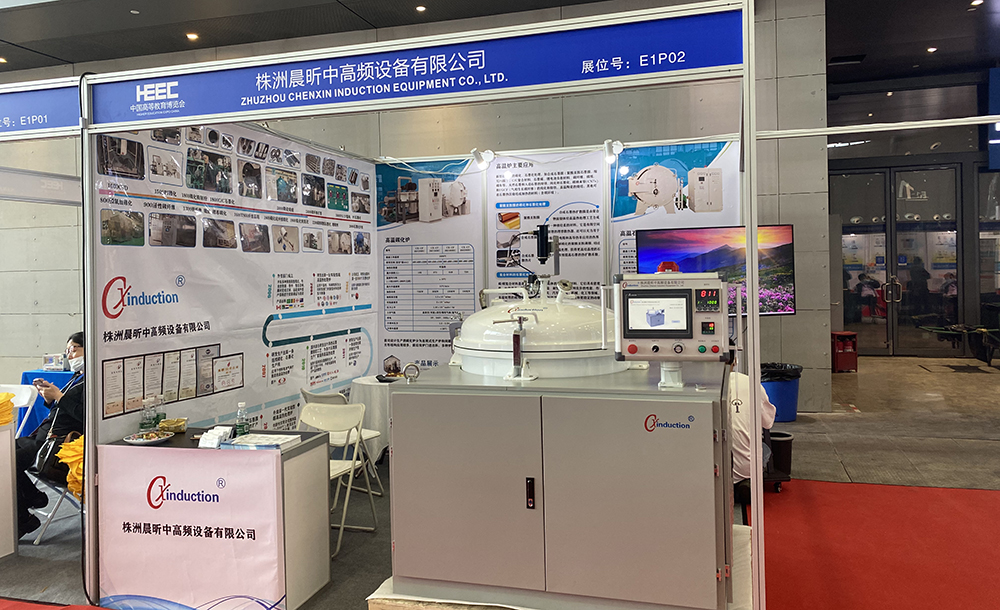

CX-GF-20/30VT is a cylindrical heating zone, vertical top loading induction heating furnace. This model can reach an ultra-high processing temperature of 3000°C, and is an ideal choice for the development and research of various new materials. The furnace is simple to operate and easy to maintain, saving time and money for research projects.

The graphitization furnace with integrated design is specially designed for laboratories, and is especially suitable for placing in places with high space requirements such as university laboratories. This model can reach an ultra-high processing temperature of 3000°C, and is an ideal choice for the development and research of various new materials.

Used in the carbonization and graphitization of carbon materials, such as high-temperature treatment of battery anode materials, high-temperature treatment of graphite powder, carbonization and graphitization of carbon fibers. It is also suitable for high-temperature sintering of precision ceramics, high-temperature components, high-temperature carbonization sintering of powder metallurgy materials, tungsten carbide and other products, and other materials that can be sintered and smelted in a carbon environment.

• Maximum long-term continuous working temperature: 3000℃ (more than 12 hours)

• Maximum design temperature: 3200℃ (maximum temperature continuous working time <2 hours)

• Working atmosphere in the furnace: nitrogen, argon

• Furnace working chamber size: Φ200×300mm (internal charging space)

• Rated output power: 60KW, the actual power used is not more than 50KW

• Rated intermediate frequency: 4000Hz

• Temperature measurement method: Double color infrared thermometer instrument and equipment

• Temperature measurement range: 1000-3200℃, (0-3200℃ full range temperature measurement, please specify when ordering, the standard configuration starts at 1000℃)

• Temperature control method: automatic program temperature control

• Equipment use: high temperature graphitization

• Cooling water consumption: 6~10m3/h

• Cooling water pressure: 0.15~0.25MPa

• Water quality of internal circulating water: distilled water or purified water

• Power supply grid: three-phase five-wire system 380V, 50Hz/60Hz

• Cooling protection: using flow, pressure, water temperature to implement multiple protections for cooling water, etc.

• Over-temperature, over-pressure, gas status, water lack and power failure alarms and automatic mechanical interlock for over-pressure protection.

• Limit heating speed: less than 60 minutes.

| Model | CX-GF20/30VT |

|---|---|

| Max Working Temperature |

3000°C (<2 hours) 2850°C (Continuous Working) |

| Usable Space (mm) Dia. * H | Φ200×350 |

| Max. Loading Capacity(L) | 10 |

|

Temperature Uniformity (ΔT between 1000°C and 2200°C) |

±10°C |

| Max. Heat-up Rate (CEDRT)* | 200 °C/min |

| Heating Power | 60 KW |

| Frequency | 4000 Hz (auto-track) |

| Ultimate Vacuum (CEDRT)* | 1.2×10-3 mbar |

| Optional High Vacuum (CEDRT)* | 5×10-5 mbar |

| Pressure Rise | 6.7×10-3 mbar/hr |

| Working Atmosphere |

High Vacuum (Optional) / Vacuum / Inert Gas (Ar or N2) Vacuum and high vacuum atmosphere is only permitted up to 2200°C. |

| Supply Voltage | 3P, 380V, 50Hz/60Hz (customized) |

| Cooling Water Pressure | 1.5~2.5 bar |

| Cooling Water Temperature | ≤28°C |

| Overall Dimensions (mm) | 1260*2760mm |

| Weight (kg) | 1500KG |

* CEDRT: Clean, Empty, Dry, Room Temperature Furnace