Chemical vapor deposition furnace (CVD furnace) is a device used to heat and gasify reaction sources such as metal halides, metal organics, and hydrocarbons under a specific pressure, and then react to produce solid deposits on the surface of the target material. It is widely used in material purification, new crystal development, deposition of various single crystals, polycrystalline or glassy inorganic thin film materials.

Chemical vapor deposition furnace (CVD furnace) is a device used to heat and gasify reaction sources such as metal halides, metal organics, and hydrocarbons under a specific pressure, and then react to produce solid deposits on the surface of the target material. It is widely used in material purification, new crystal development, deposition of various single crystals, polycrystalline or glassy inorganic thin film materials.

One or more controlled carbon source gases are cracked at high temperature and passed into the shaped preform. In the long-term heat treatment process, it gradually deposits in the voids and gradually transforms the carbon into larger graphite crystals, forming a high-strength carbon fiber reinforced carbon-carbon composite material

• Maximum temperature: 1300°C, Working temperature:1000°C - 1200°C

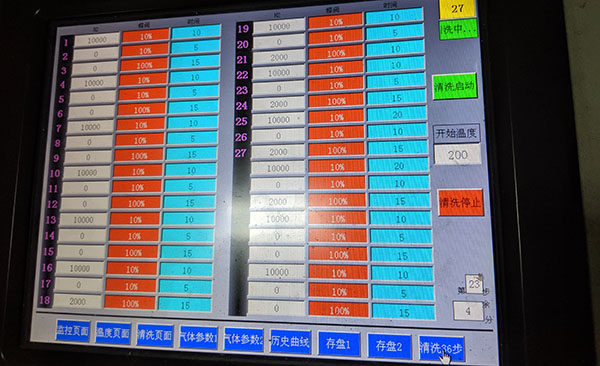

• It can accurately control the gas flow and pressure, the deposition gas flow in the furnace is stable, and the pressure fluctuation range is small.

• Multi-channel deposition gas path, uniform flow field, no dead corners of deposition, and good deposition effect.

• Effective treatment of highly corrosive exhaust gas, flammable and explosive gas, solid dust and low melting point viscous products produced by deposition.

• Using anti-corrosion vacuum unit, long continuous working time and low maintenance rate.

• Vertical Bottom Loading with a single chamber or multi chambers design for high production capacity. The shell and door are water-cooled jacketed. Both the outer and inner layer of the furnace shell and door is made of SUS304 stainless steel.

• Stable hydraulic lifting system for the chamber door or bottom. Ground guide rail and skip car for bottom loading models.

• Induction coil covered by high-quality alumina coating in order to avoid short circuits between coil and carbon felt.

• High vacuum pneumatic valves equipped with position indicators in order to automatically control the vacuum and gas supply system.

• Over-temperature, over-pressure, gas status, water lack, and power failure alarms and automatic mechanical interlock for over-pressure protection.

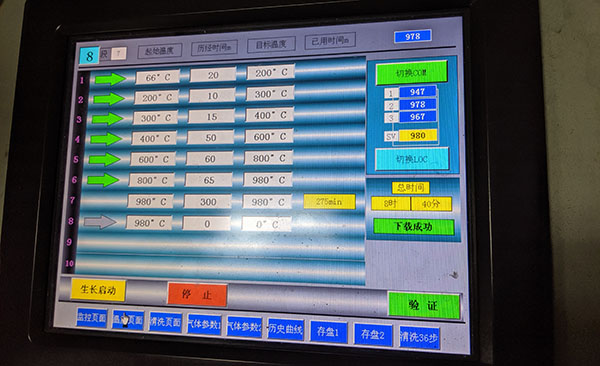

• All the running parameters are stored in the PLC system. All stored parameters can be transferred into your personal computer through a USB port.

• High precision smart temperature controller which can store 20 programs with a total of 400 segments.

| Model | CX-CVD20/30VB | CX-CVD30/40VB | CX-CVD40/100VB | CX-CVD50/100VB | CX-CVD60/100VB | CX-CVD60/160VB |

|---|---|---|---|---|---|---|

| Max Working Temperature | 1300°C | |||||

| Usable Space (mm) W×H×L | Φ200×300 | Φ300×400 | Φ400×1000 | Φ500×1000 | Φ600×1000 | Φ600×1600 |

| Max. Loading Capacity(L) | 9 | 28 | 125 | 196 | 282 | 452 |

|

Temperature Uniformity (ΔT between 1000°C and 2200°C) |

±10°C | |||||

| Max. Heat-up Rate (CEDRT)* | 15°C/min (RT~1500°C), 10°C/min (1500°C~2500°C), 5°C/min (2500°C~3000°C) | |||||

| Heating Power | 100 KW | 160 KW | 180 KW | 180 KW | 180 KW | 180 KW |

| Frequency | 1000 Hz | 1000 Hz | 1000 Hz | 1000 Hz | 1000 Hz | 1000 Hz |

| Ultimate Vacuum (CEDRT)* | 1.2×10-3 mbar | |||||

| Optional High Vacuum (CEDRT)* | 5×10-5 mbar | |||||

| Pressure Rise | 6.7×10-3 mbar/hr | |||||

| Working Atmosphere |

High Vacuum (Optional) / Vacuum / Inert Gas (Ar or N2) Vacuum and high vacuum atmosphere is only permitted up to 2200°C. |

|||||

| Supply Voltage | 3P, 380V, 50Hz/60Hz | |||||

| Cooling Water Pressure | 1.5~2.5 bar | |||||

| Cooling Water Temperature | ≤28 °C | |||||

* CEDRT: Clean, Empty, Dry, Room Temperature Furnace