One or more controlled carbon source gases are cracked in the preheated gas distribution plate, and grown on copper foil substrates (including ruthenium, iridium, nickel and other metal substrates), achieving >95% single layer graphene coverage at a time, through multiple etching and deposition, 100% full coverage single-layer graphene growth can be achieved.

Chemical vapor deposition furnace (CVD furnace) is a device used to heat and gasify reaction sources such as metal halides, metal organics, and hydrocarbons under a specific pressure, and then react to produce solid deposits on the surface of the target material. It is widely used in material purification, new crystal development, deposition of various single crystals, polycrystalline or glassy inorganic thin film materials.

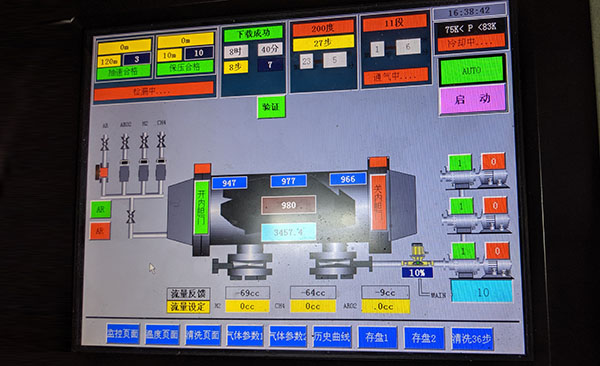

One or more controlled carbon source gases are pyrolyzed by a gas distribution plate set in a CVD furnace, and flow through the carbonized resin-reinforced carbon fiber matrix in a low vacuum state to fill the gaps of the matrix material and further carbonize to increase the density. Long-term heat treatment causes the carbon to form larger graphite crystals and obtain higher-performance carbon-carbon composite materials. A variety of gases with higher requirements flow into the heated matrix material in the furnace, and the temperature, pressure, flow rate, and carrier gas volume can be precisely controlled. A single layer of graphene with a two-position structure can be obtained on the surface of the matrix material.

• Maximum temperature: 1300°C, Working temperature:1000°C - 1200°C.

• It can accurately control the gas flow and pressure, the deposition gas flow in the furnace is stable, and the pressure fluctuation range is small.

• Multi-channel deposition gas path, uniform flow field, no dead corners of deposition, and good deposition effect.

• Effective treatment of highly corrosive exhaust gas, flammable and explosive gas, solid dust and low melting point viscous products produced by deposition.

• Using anti-corrosion vacuum unit, long continuous working time and low maintenance rate.

• Vertical Bottom Loading with a single chamber or multi chambers design for high production capacity. The shell and door are water-cooled jacketed. Both the outer and inner layer of the furnace shell and door is made of SUS304 stainless steel.